In this article we are going to see the review of the Sunlu T3 3D printer. A plastic printer that is easy to assemble, practical to use and at the right price!

There are a lot of 3D printers on the market and finding your way around is no easy matter. Different materials, different sizes and different times for different uses. In this review where we will discover the strengths and weaknesses of Sunlu’s Terminator 3 we will try to clarify some fundamental points as well.

The Sunlu T3 is suitable for those approaching 3D printing for the first time but can also give satisfaction to those looking for a small upgrade. The size and the more than affordable price, although there are cheaper ones, combined with mechanical and electronic technology make it really suitable for a good part of the public. Let’s find out the reasons together.

Unboxing and editing | Sunlu T3 3D printer review

Once the cardboard box is opened, we will find our 3D printer divided into two parts and ready to be assembled.

Do not worry, the assembly is actually nothing more than joining the two fundamental parts of the structure and everything takes place in a matter of minutes.. By following the instructions, and if necessary watching the videos on Sunlu’s YouTube channel, everything will run out smoothly. Inside the package we find a series of numbered sachets with a dozen screws inside and a series of Allen keys necessary for fixing the structure.

As mentioned, you do not need great technical skills to be able to assemble the printer and if you have done everything correctly you will be almost ready to print your first objects.

Inside the package as well as our printer and everything you need to mount it we will also find a 200 gram PVA coil, a small cutters for any finishing touches and a set of keys to disassemble the extruder if you ever need them.

Let’s see the technical sheet

- Print volume: 220 x 220 x 250mm

- Print speed: 20-250mm/s

- Printing accuracy: ± 0.1 mm

- Usable materials: 1.75mm PLA Meta, PLA & PLA +, carbon fiber, ABS, PETG, HIPS, WOOD, PCL, TPU

- Noisiness: ≤ 45 dB

- Maximum extruder temperature: 260 °C

- Maximum working plate temperature: 100 °C

- Dimensions: 440×400×470(mm)

- Weight: 7.25 Kg

Initial setup and software

Before starting to print, there are still a few small steps to take. The printer boasts a good automatic positioning system but to have really well done prints it is good to perform a manual leveling. First you will need to physically adjust the wheels located under the printing plate to adjust the height between the extruder and the work plate, or magnetic mat.

To do this, it is best to place a sheet of paper (a classic A4 printer will do) between the extruder and the plate.. The same procedure will then be done for all the points where the extruder moves or at least for the center and for the four corners.

The operation may seem more difficult than it really is and thankfully once again Sunlu comes to our rescue with a series of video tutorials on their YouTub channele.

As for the software we used what Sunlu herself recommends, Cura. Our T3 is not present among the choices within the Slicer program but Sunlu is ready to suggest one with the same characteristics.

From here you will literally open a world and you can decide to upload files ready to be “sliced” through Cura or rely on a 3D modeling program before going to convert the file again through Cura.

Once you have done these steps, you can load your file into a Micro SD memory and start printing. All of course after loading the reel through a couple of simple steps.

For our part, we tried both solutions and if at first we were “satisfied” with creating prints with already beautiful files that are ready, then we had fun designing some more personal print elements.

How is the print quality? | Sunlu T3 3D printer review

We have probably come to the most important point of this Sunlu T3 review, the printing tests.

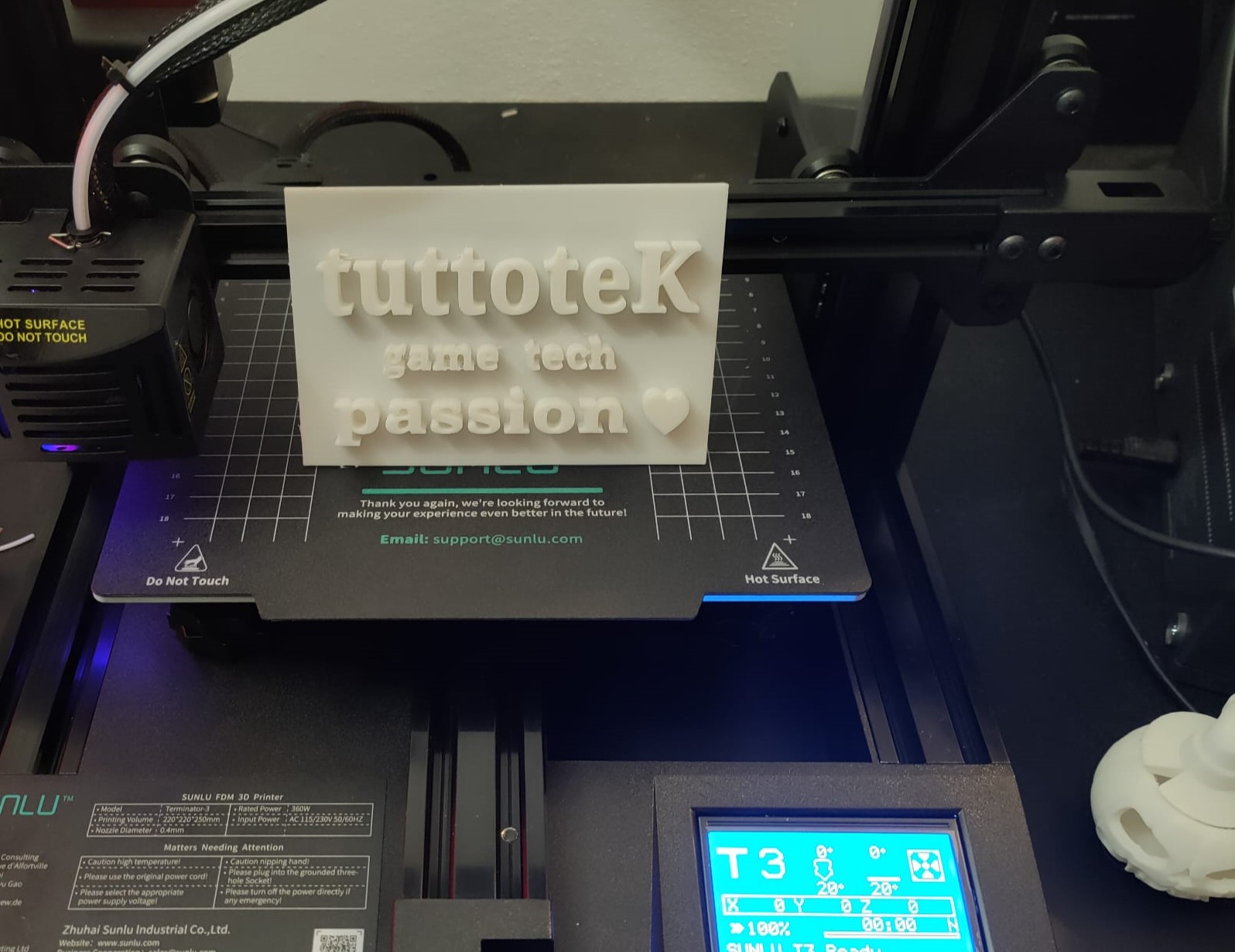

First of all it is good to specify that we have used the material that was provided to us, and that you will find in the package, together with the printer. The print quality is not bad at all as can be seen from the images just above. Net of some smudging caused mainly by the original files that we used to create the plastic models, we cannot complain.

As you can see from the cover photo with prints deriving from files of your own creation, everything improves and not a little.

However, the most noticeable artifacts in prints are also caused by the speed of the printer. There is no doubt that being able to print at 250 mm / s will allow us to have what we need faster but it is also true that on prints rich in detail a print at 50mm / s could be the best choice.

In short, the printing speed which is obviously a point in favor could prove to be a cross and delight of the same.

The great strength certainly lies in its simplicity of use. Despite a few small steps between assembly and preparation anyone can start printing even without any (or almost) basic skills.

We did not encounter nozzle clogging problems and when the filament in the reel broke the printer stopped warning us, and after putting everything back in order it will start again from it had left with a surprising solution of continuity.

Who should buy this Sunlu Terminator 3?

In conclusion, this Sunlu T3 3D printer allows us to approach the world of 3D printing in total safety and simplicity.

With countless security tools, ease of assembly and setup as well as ease of use, it’s a great printer to start with. The speed of 250mm / s allows us to print quickly and with good attention to detail even if in some situations going down to lower speeds could be the right choice.

The possibility of using different materials is excellent and Sunlu’s customer care is also excellent, providing many tutorials able to accompany the user in taking his first steps in the world of 3D printing.

If you are looking for a fairly inexpensive printer that gives good satisfaction with this Sunlu T3 you will not be disappointed.

Remember that for other contents related to the world of electronics you can take a look at our dedicated page.

Points in favor

- Ease of use

- Ease of assembly

- Speed up to 250 mm / s …

Points against

- … although sometimes it is better to go down to 50mm / s for higher quality

- A little bulky

Leave a Reply

View Comments