Apple wants to increase its commitment to incorporate recycled materials into all of its products, including a new 2025 milestone of use 100% recycled cobalt in all Apple-made batteries. What’s more, by 2025, magnets in Apple devices will use fully recycled rare earth elements. And all circuit boards created by Apple will use the 100% recycled tin solder and 100% recycled gold plating.

Apple will only use recycled cobalt in batteries in 2025

In 2022, the company significantly expanded its use of essential recycled metals. And now he gets more than two-thirds of all aluminum, nearly three-quarters of all rare earths and more than 95% of all tungsten in Apple products come from recycled content.

Tim Cook, Apple’s CEO, explains: “Every day, Apple innovates to create technology that enriches people’s lives while protecting the planet we all share. From the recycled materials in our products to the clean energy that powers our operations, iOur commitment to the environment is integral to everything we do and who we are. So we will continue to move forward in the belief that great technology should be great for our users and the environment.”

“Our ambition to one day use 100 percent recycled and renewable materials in our products goes hand in hand with Apple 2030 – our goal to make products carbon neutral by 2030,” said Lisa Jackson, vice president for Apple’s environment, policies and social initiatives. . “We are working to achieve both with urgency and drive innovation across our industry in the process.”

More and more 100% recycled products

Apple has increased significantly the use of 100% recycled cobalt certified for the past three yearsmaking it possible to enter all Apple-made batteries by 2025.

Mediaworld: the best price guaranteed!

In 2022, a quarter of all cobalt in Apple products came from recycled material, up from 13 percent a year earlier. Cobalt is a crucial material in the batteries used in most consumer electronics, including Apple devices. Apple-made batteries found in iPhones, iPads, Apple Watches, MacBooks, and many other products account for a significant portion of the company’s use of cobalt.

The company’s use of 100% certified recycled rare earths has also grown significantly in the past year, rising from 45% in 2021 to 73% in 2022. Since the first introduction of recycled rare earths in the iPhone 11 Taptic Engine, Apple has expanded the material’s use across all of its devices, including all magnets. They represent the largest percentage of rare earth use, and by 2025 they will be recycled.

Apple also wants help people living in mining areas improve their living conditions and find new opportunities. For this reason, Apple works with experts such as the Fund for Global Human Rights to support those who defend nature and human rights in the most vulnerable areas, such as the region of African Great Lakesin.

Zero plastic goal

Another of the goals that Apple has set for 2025 is to eliminate plastic from its packaging. To achieve this ambitious goal, Apple has invested in the innovation of fiber solutions to replace packaging elements such as protective films, wraps and foam pads.

This has allowed Apple to reduce 96% of plastic in the packaging footprint of the company. To address the remaining 4%, Apple is looking to eliminate the use of plastic labels, lamination and other small applications. For example, Apple has created an scustom printer to print directly on iPhone 14 and iPhone 14 Pro boxes, avoiding most labels. In addition, a new overprint varnish used in the packaging of iPad Air, iPad Pro and Apple Watch Series 8. This has saved over 1,100 tons of plastic and over 2,400 tons of carbon dioxide.

Apple and the new technologies for recycling

Apple is working to create new research and development opportunities for disassembling and recycling end-of-life products. This progress is the result of great efforts, including collaborations with leading research centers and the Material Recovery Lab di AustinTexas, where Apple engineers and experts are looking for creative ways to reuse materials from Apple products and helping make design choices that ffacilitate disassembly and recovery.

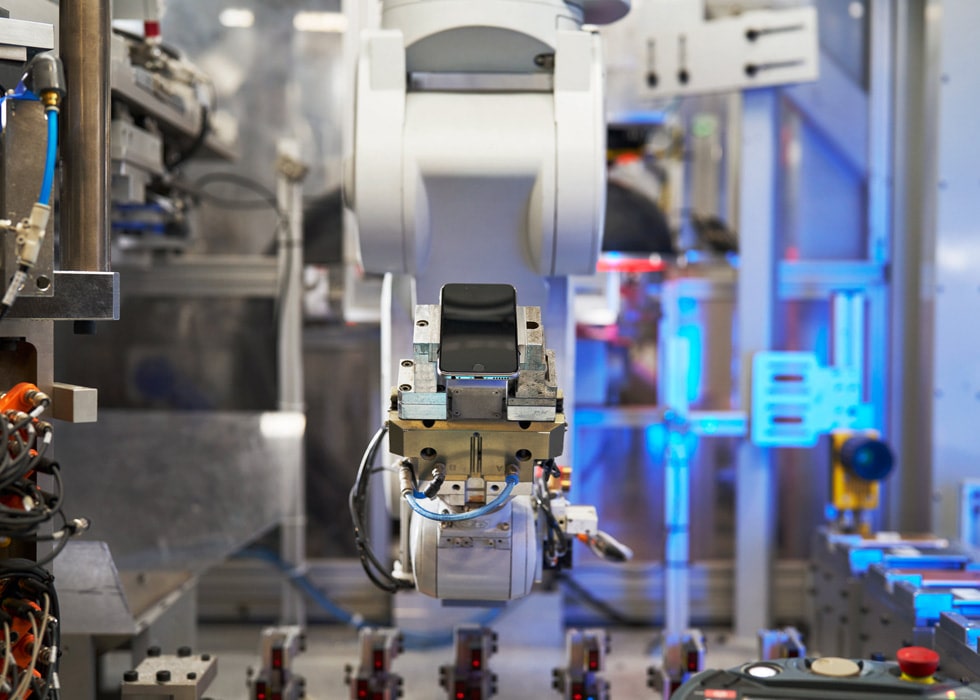

One of the tools that Apple uses for this purpose is Daisy, the robot that disassembles iPhones and separates batteries from other components. This allows specialist recyclers to recover cobalt and other materials, such as lithium. Apple estimates that as of 2019 Daisy has extracted more than 11,000 kilograms of cobalt from batteries and returned them to the secondary market. Daisy also helps recover rare earth elements, which are often lost in traditional electronics recycling processes.

Daisy is not the only example of how Apple innovates in the field of recycling and disassembly. The company has also created Dave, a robot who disassembles Taptic motors and recovers its rare earth elements. Dave is now in use at a recycling partner in China.

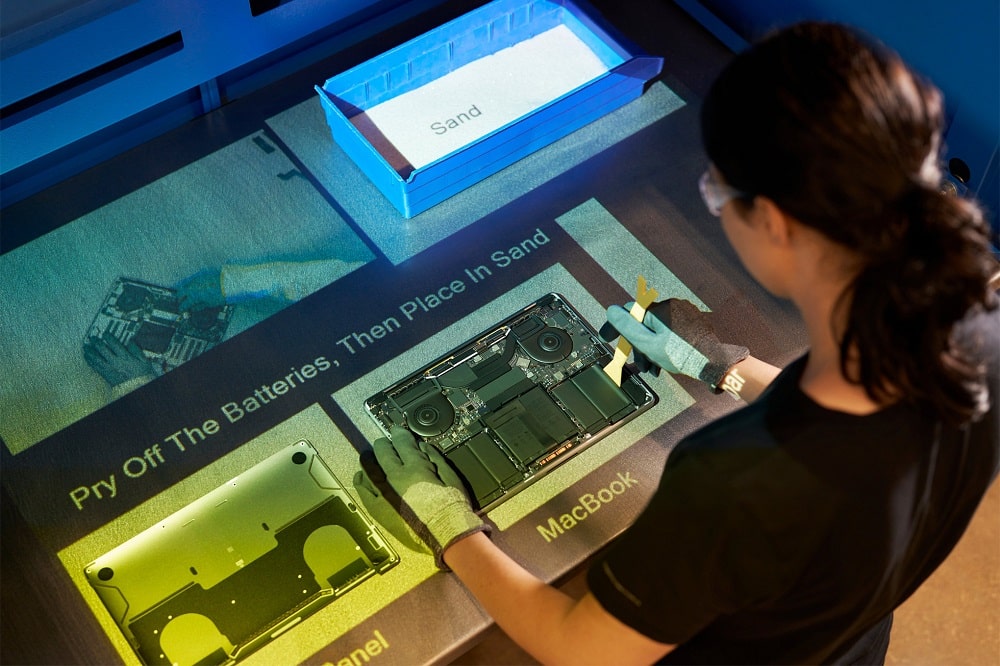

Apple has also started to use augmented reality (AR) systems based on overhead projectors to guide the teardown of devices such as MacBooks and iPads. The system projects video images directly onto a work surface. The company also supplies Apple Recycler Guides to global recyclers to optimize material recovery while safeguarding human health and safety.

As recycled and renewable materials can contribute arreduce the carbon footprint of each product, advanced recovery is also moving Apple closer to its ambitious 2030 goal.

Leave a Reply

View Comments