CNC machining is one of the most widespread in the mechanical industry because it allows you to create pieces with great precision. Although CNC machining machines are very expensive, there are alternative solutions today

CNC machining, an acronym for Computer Numerical Control, is a process of automated production widely used in the manufacturing industry. It is a machining method that uses numerically controlled machines to produce precision parts using predefined programming code. Different materials can be worked including metals, wood, plastics and stone. Even if they can be very expensive processes! This is why it can be useful to evaluate an online CNC machining quote.

CNC machining: what it is

The CNC machining process begins with the CAD model design of the object to be created, which is then converted into a code CAM programming (Computer Aided Manufacturing). This code contains precise instructions on the shape, dimensions and geometry of the piece to be made. The code is then loaded into the CNC machine. These steps usually require the intervention of an expert person.

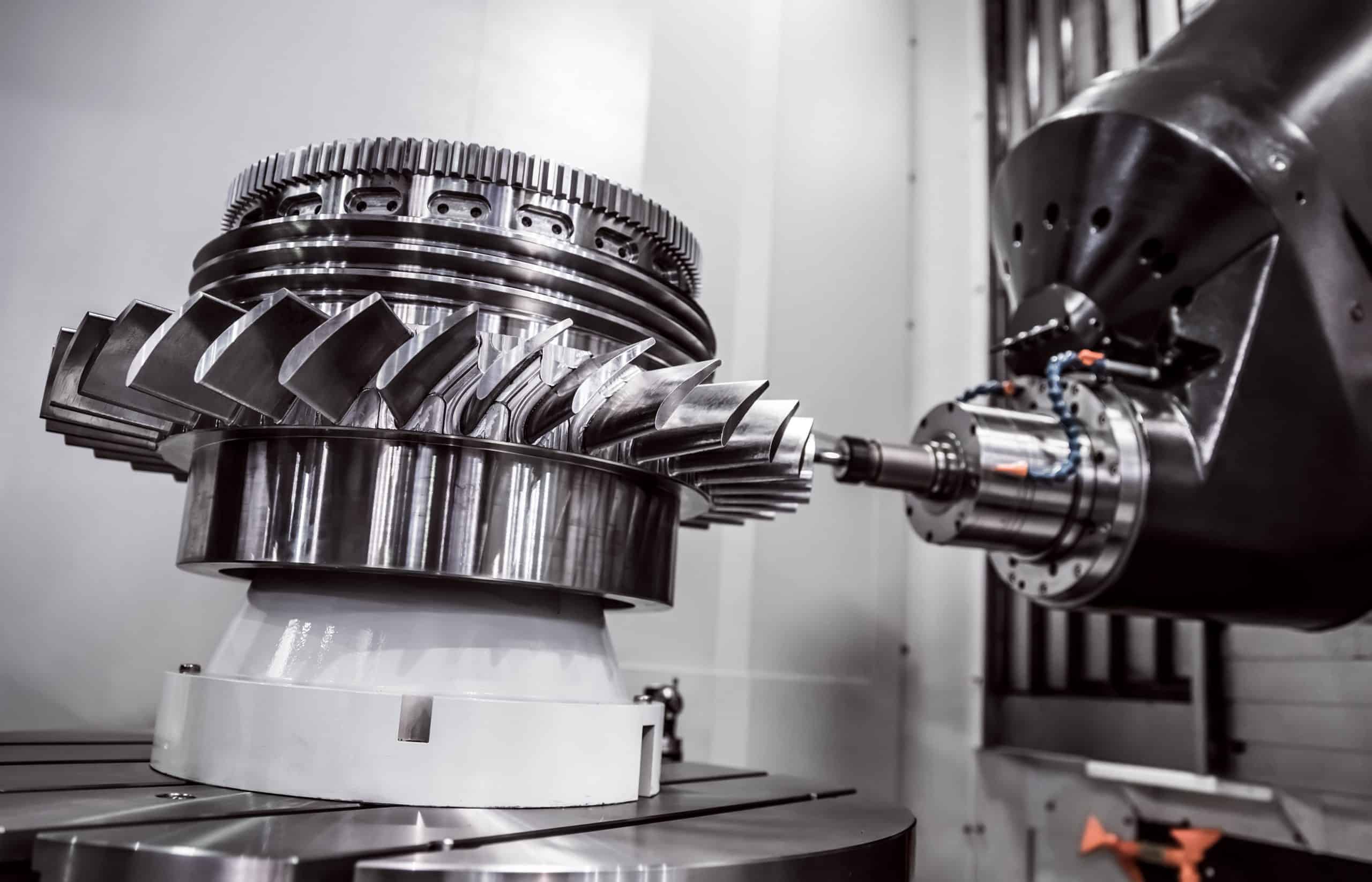

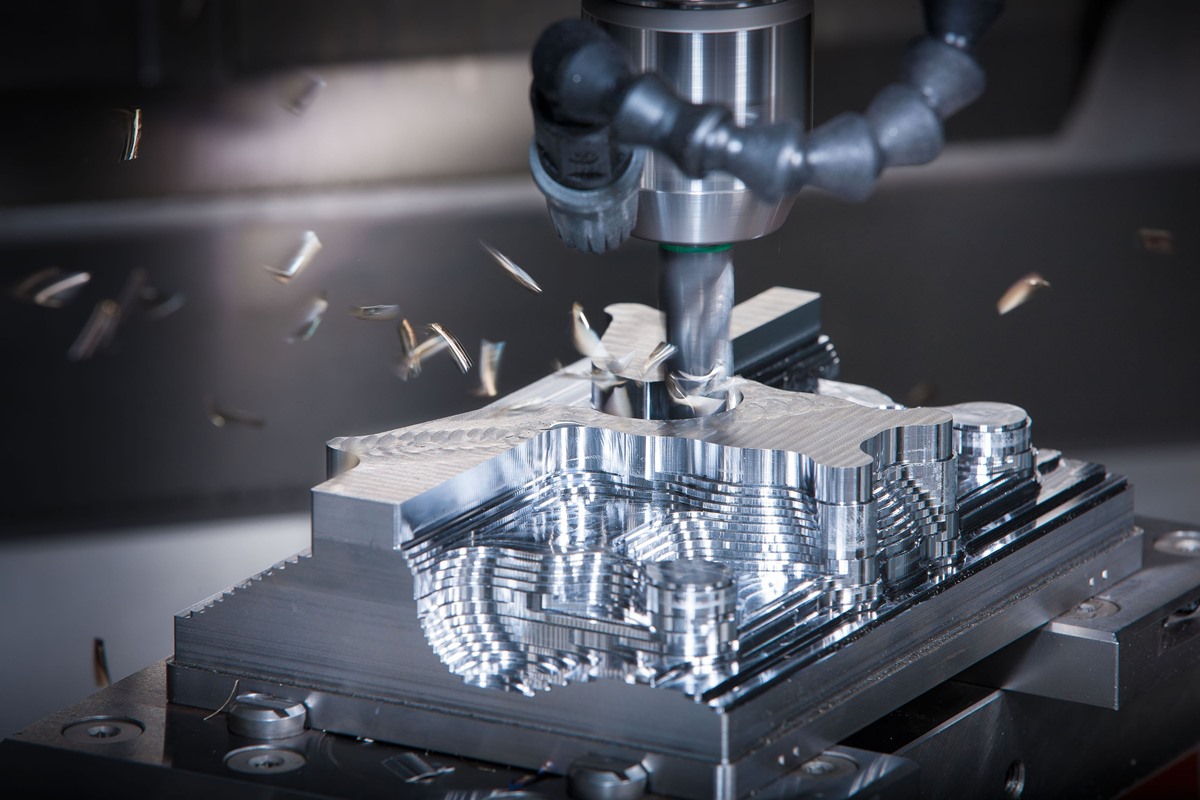

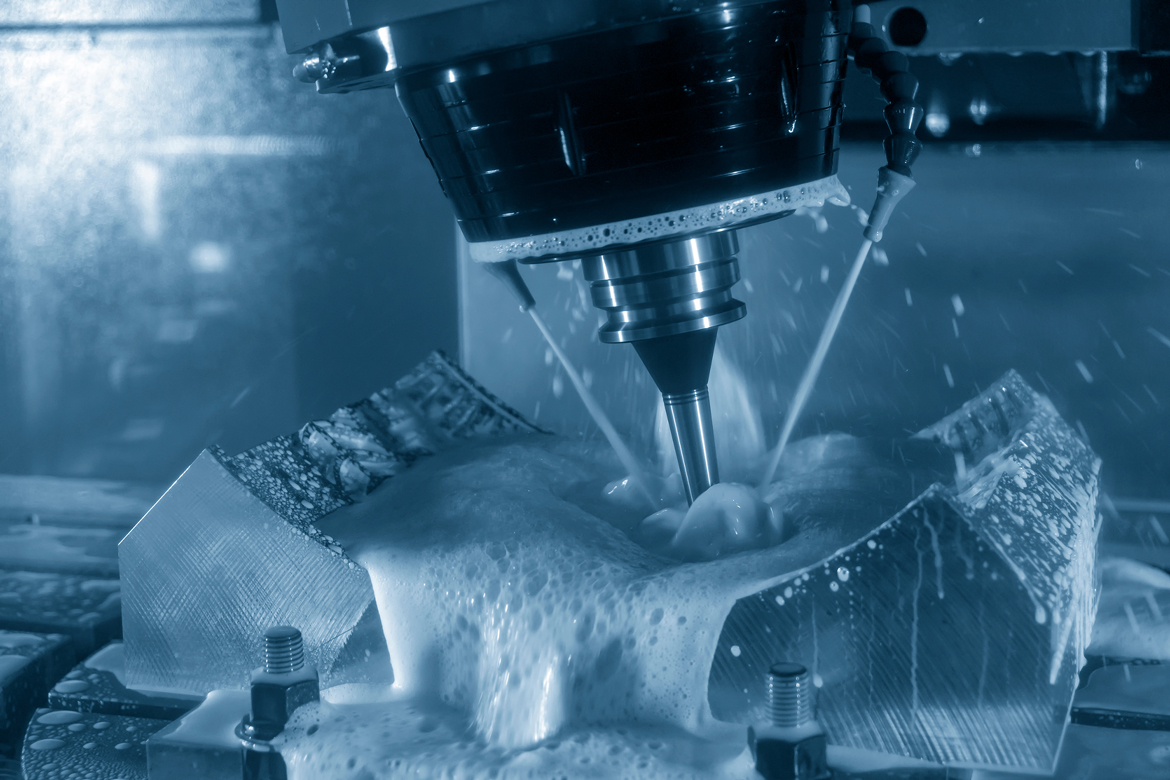

Once the code is uploaded, the CNC machine starts working the base material which is usually a block of metal, wood or other. The machine uses cutting tools, such as cutters or drills, which remove material very precisely in order to recreate the computer-designed pattern.

During CNC machining, the base material is usually fixed firmly on a work table or clamping fixture. The CNC machine it then moves the cutting tools along the different axes, cutting, drilling, milling or notching the material according to the specifications of the programming code.

CNC machining offers many advantages over traditional machining methods. For one thing, it allows for greater precision and repeatability, as CNC machines can perform the same motions and operations consistently and accurately. It also allows for a greater automation and reduces dependence on human laborimproving efficiency and reducing errors.

CNC machines can be used for a wide variety of applications including manufacturing components for the automotive, aerospace, electronics, medical and many other industries. They are very precise and can produce large quantities of all identical parts once the program is prepared.

The cost problem

Generally the CNC machining machines are very expensive, especially if high precision or production speed are required. That’s why it is sometimes convenient to rely on external services, especially when very high volumes of workpieces are not required. Requesting an online quote for a CNC machining is really very simple and takes little time. Simply upload the CAD file, specify the material and number of pieces required. In a few moments we will have an estimate of the production cost.

Many online CNC machining services also offer a counseling part to help you choose the most suitable material for example. Furthermore, the whole process is carried out with the utmost secrecy, in order to preserve industrial secrets.

That’s all from the electronics section, keep following us!

Leave a Reply

View Comments