Batteries to be recycled are a big issue for car manufacturers, the robot Commas.

The namesake agencybased in Turin, of the group Stellar, has the Flex-DB project in the pipeline. Born for the flexible disassembly of batteries.

Comau robot disassembles and recycles electric car batteries, site source

Comau robot disassembles and recycles electric car batteries, site source

How the robot arm made by Comau works

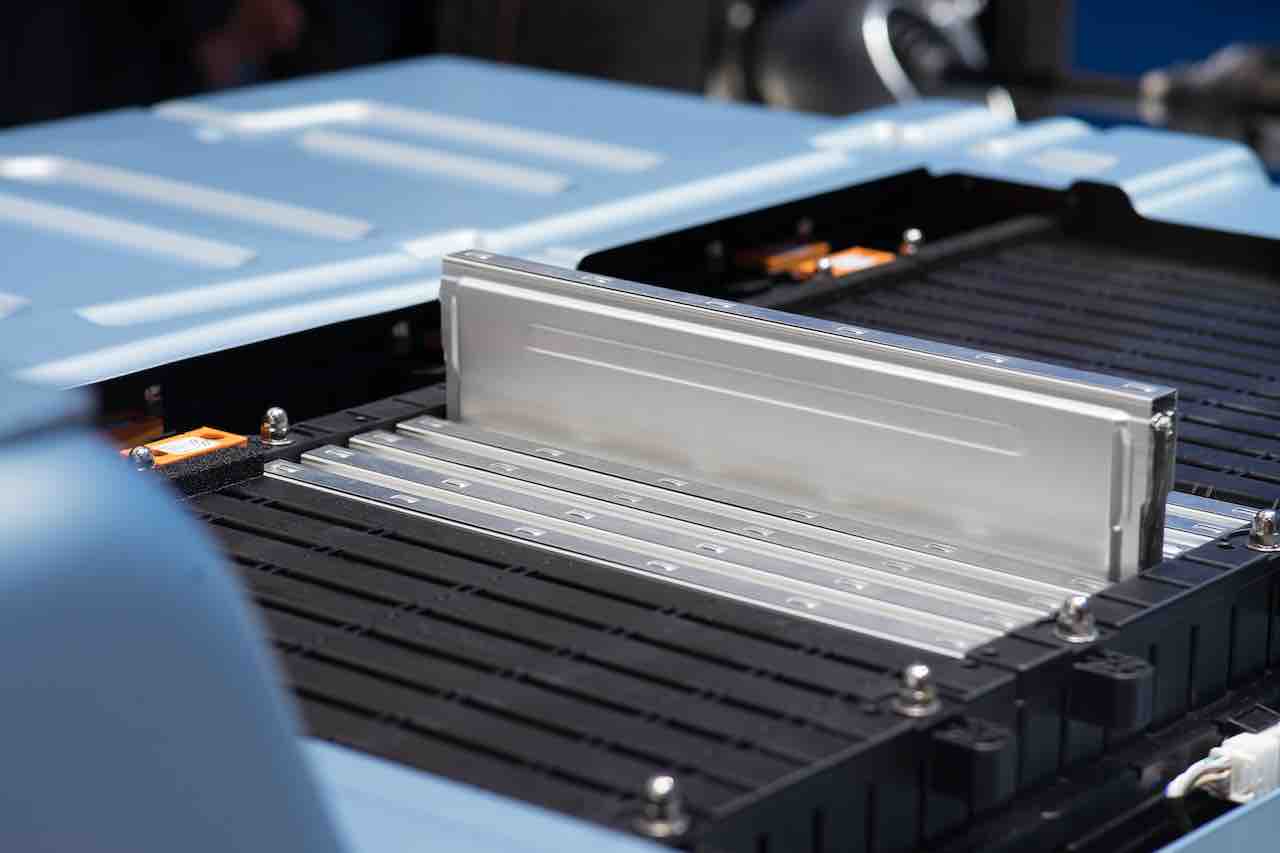

Flex-BD is a robotic system that automates the entire process of disassembling electric batteries exhausted through a highly flexible, repeatable and standardizable process. Once the proof-of-concept was validated, Comau expanded its scope to include the reuse of batteries in the automotive sector.

Thus, Comau, in collaboration with other partners within the community UE EIT Manufacturingcarries forward a project and new steps towards greater sustainability within eMobility.

Choose Amazon Prime for your purchases, it’s free for 30 days

Based on the expected production volumes of electric batteries in Europe in the coming years, Comau estimates that, in all likelihood by 2030, there could be over 1 million discarded batteries in the EU for reuse. Indeed, Comau intends to anticipate what it believes is a growing market demand for powerful electric battery recycling and reuse solutions. At the same time, it will allow companies to reduce waste and optimize the reuse of the raw materials contained in the battery packs.

Efficient and sustainable recovery of battery modules

Flex-BD represents a significant improvement in manual disassembly processes that often involve repetitive and arduous tasks, as well as contact with potentially harmful substances. The recovery of battery modules and their components is made more efficient and sustainable, with a positive impact on the health and safety of operators. On the other hand, with battery regeneration, fully automatic handling of low-charge batteries minimizes risks to both operators and disassembly equipment. Unlike the material recovery and recycling process, where the battery is completely discharged and destroyed, regeneration is done by maintaining a low but active battery charge.

The Comau robot disassembles and recycles the batteries of electric cars, source Depositphotos

The Comau robot disassembles and recycles the batteries of electric cars, source Depositphotos

The operation of the Flex-BD system is as intuitive as it is innovative. The battery packs are introduced individually into the special cell where a high-capacity Comau NJ industrial robot automatically carries out the procedure and changes its end effectors according to the required application. In a typical recycling application, for example, the robot unscrews the battery cover, changes the pliers to remove the cover, re-engages the screwdriver to unscrew the modules and then, using the pliers, moves the pieces to a storage area dedicated. Furthermore, Flex-BD is designed for a highly flexible programming approach based on low use of codes, state-of-the-art environmental perception techniques and robot responsiveness, and the entire disassembly cycle is defined via CAD. The use of LowCode programming also allows operators to redefine the cycle quickly and easily without the need to reprogram the robot.

Leave a Reply

View Comments