We have been talking about for years now 3D printing. Someone had said there would be a 3D printer on every desk, but the thing you are not has come true for reasons of practicality. What has come true though, is that today many companies use the 3D printing to bring innovation. Elmec this phenomenon he understood it well and he already founded Elmec 3D years ago: his division for industrial 3D printing. And precisely on this theme, Elmec proposes an annual event called “Expo of the IMPOSSIBLE“, which is already in its second edition. Last year he was mostly talking about innovative materials for aerospace use. In 2023 the EXPO of the IMPOSSIBLE was held on July 12 on the Elmec campus in Brunello, in the province of Varese. The theme of this edition was the 3D printing for medical innovation.

The Expo of the IMPOSSIBLE

The expo, presented by our Fjona Cakallihad as its first guest Martina Ballerio: the head of the 3D division of Elmec. Ballerio began by speaking of the history of Elmec, which started from the mechanographic systems to become one very important reality on the territory, especially in the field cybersecurity. The company has many souls; 3D printing is the latest addition, but also one of the most promising.

As a company committed to innovating and improving the world we live in, we want to highlight the fact that 3D printing is not just about innovation within the manufacturing industry. But, as we were able to see thanks to the numerous experiences and business cases presented during the event, 3D technology is also a crucial enabler for concretely improving people’s lives

Martina Ballerio

The interventions of the two guests, both very interesting, focused on the use of 3D printing in the medical field. Only part of the results are already being used in hospitals, but the promises for the health of the next generations are fascinating.

Gabriel Liguori’s cardiac tissues

Gabriel Liguori

Gabriel Liguori

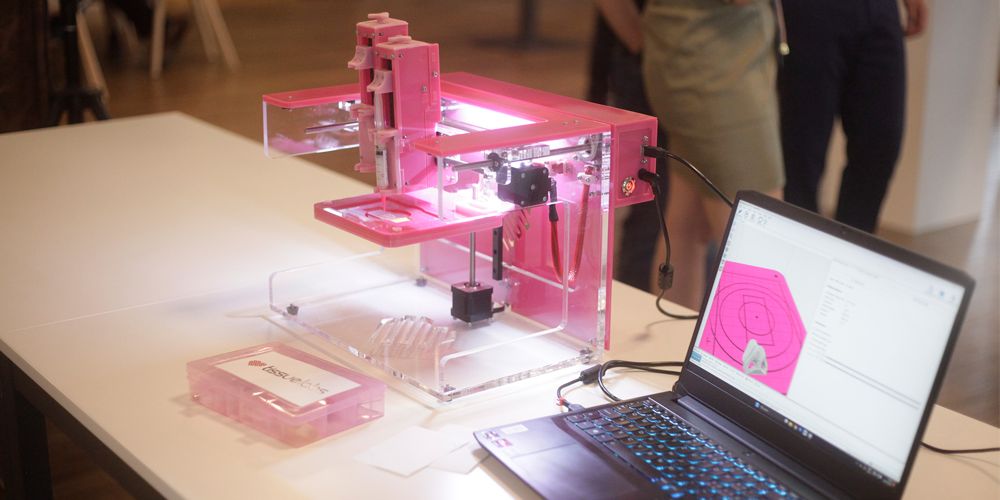

Gabriel Liguori was born in Brazil in 1989 and, unfortunately, he suffered from a heart problem from an early age. This though it doesn’t discourage him; on the contrary, it ignites a strong determination in him: decides to dedicate his life to helping people with the same problem as him. After one medicine degree in the on the country and a PhD in Germanywith a academic career well established founds TissueLabs. TissueLabs’ goal is simple but also extremely ambitious: print the first transplantable heart on a human being.

Liguori shows the public his 3D printer prototype for biological material and explains that there is still a long way to go. Today we manage to create fabrics with cells that remain aggregated with each other and we also manage to printing of blood vessels. It’s not a whole organ but they are important steps forward.

Today experiments are being carried out above all on non-complex organ tissues. In mice, for example, it is already possible to rebuild the thyroid and ovaries. In humans, however, the printing of new skin for burn victims is being tested.

The problem with printing biological material, Liguori explained to us, is that this it’s not stiff; for which it becomes difficult to deposit accurately successive layers of cells. Indeed, according to the doctor, the print of biological material it is in 4D and not 3D. This is because it is also articulated by various stages over time. There is a first phase of preparationa second phase of press in which the cells are deposited and a phase after printing in which the cells mature and the real fabric is formed.

To create great functioning organs are still there some problems to solve. First understand which is the biomaterial to use and from which cells to start. Second, figure out how to print special fabrics. Finally, succeed in also print all the blood vessels to ensure that the ogano remains alive.

Chiara Comelli and the reconstruction of the face

Dr. Chiara Copelli

Dr. Chiara Copelli

Prof. Chiara Comelli, of the Policlinico di Bari, is another of those doctors who work with passion for allow their patients to resume a normal life. Comelli is one maxillofacial surgery specialistthat is, problems with the face and the underlying skeleton. Unfortunately, there are many situations in which a reconstruction of the face becomes necessary. Sometimes due to an accident or a malformation, sometimes for oncological reasons. Giving the right shape and position to the bones means restore dignity and a normal life to the patient.

3D printing, for the work of Chiara Comelli is proving itself extremely helpful on many fronts. First, it is possible plan much more precisely interventions because the doctor may be holding one 3D reconstruction of the patient’s situation. Acting quickly also means reducing the likelihood of problems during the operation. Furthermore, with 3D printing, guides are made to be applied directly on the bones to know exactly where to go to operate. The next step will be to print also gods patient-specific supports to hold together and stabilize the new bone structure.

Unfortunately, what we still cannot do today is to print a biologically compatible bone. For that, traditional methods are still used. However, we can print prostheses. That is, we can make gods replaced in non-biological material but still very important. For example, it is possible rebuild a cheekbone or part of the skullcap of the patient.

Prof. Chiara Comelli closes her presentation talking about problems still open; first of all that of medical certifications. Banally, he explains to us, the material with which you print is certified, but the object you are going to print is not. So, one more is needed important regulatory work.

The round table on the innovation of 3D printing

The Expo of the IMPOSSIBLE closes with a discussion in which other participants are added as well who bring their experiences in terms of innovation through 3D printing.

Emanuele Schiavon, Solution architect of Omron Industrial Automation, shows us a robotic arm playing checkers. 3D printing has been useful to produce adapters that make it compatible with tools from other manufacturers and allowed to create a touch sensor. The robot, in fact, is covered with a soft structure which, in contact with an obstacle, stops the movement. Clearly, this is capable of greatly reduce workplace accidents.

Donato Cinielloof Extró cosmetics, told us instead of a designer razor that went out of production a century ago. Unfortunately, the one for moving blade razors is a market very niche and mass production would not have been economically viable. Thanks to 3D printing, however, it was possible start making it again anyway with an acceptable price.

Con Francesco Checchini Manara, Co-founder and CEO of Gondola Medical Technologies back to the medical field. Gondola produces a medical device for the treatment of gait and balance symptoms caused by neurological disorders. In practice, it is a device where the patient inserts his foot to receive a very precise stimulation. Being able to make the structure with a 3D printer made it possible to do the custom cast precise of the patient’s foot and to obtain a smallest and lightest device, manageable even on the go. Furthermore, the greater precision of the calculation also allows a much more effective treatment.

In the end, Ivan Guerini, Product & Design Manager of Isinnova told us about the Letizia project. Letizia points to help walk again people who have had lower limb amputations for unnatural causes. Obviously, the goal is to help i wounded landmine survivors in countries at war. The challenge, for Letizia was produce the device at a very low cost and capable of being manufactured on site. This result was possible only thanks to the innovation brought by 3D printing.

Leave a Reply

View Comments