TurboAlgor Engineer Ascani was designed for reduce CO2 emissions in one of the most polluting sectors of all industries: chillers. This will greatly improve the environmental impact of the refrigeration sector, responsible for About 20% of energy consumption in the world.

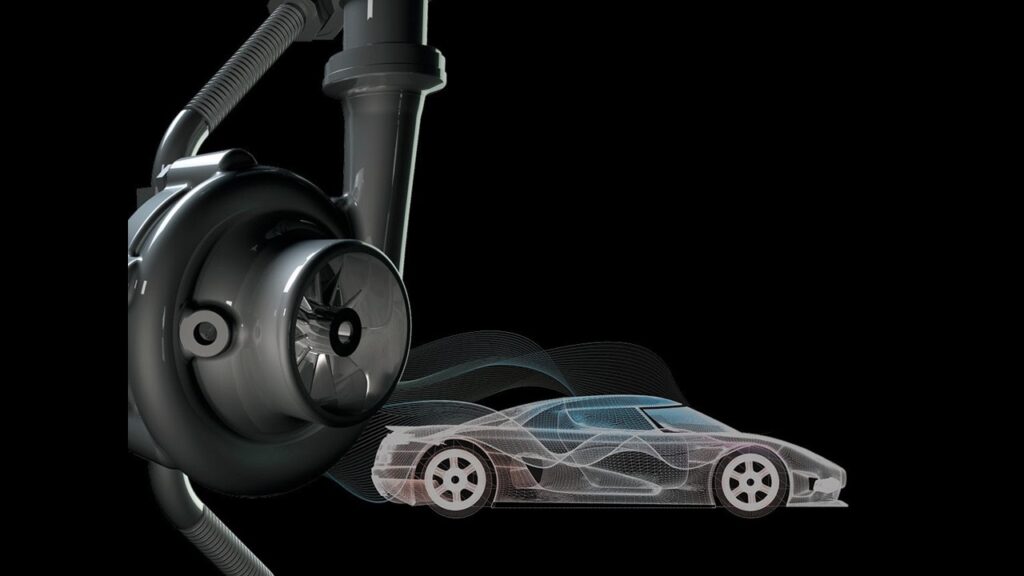

Turboalgor is one spin-off of the Angelantoni Group, and the aim of the technology is to reduce the pollution and environmental impact associated with industrial refrigeration systems, through the use of the turbo of cars.

Ascani’s intuition of Turboalgor to reduce CO2 emissions from chillers

Maurizio Ascani is an engineer who worked in automotive sectorand throughout his career. The intuition behind his innovation is that of recover part of the energy lost in the lamination valveand, where the coolant changes from a high to a low pressure.

By inserting a heat exchanger it is possible to recover a fraction of this energy, and even improve the cooling capacity of the system.

There are three patented and operational solutions: a turbo car e a free piston expander combined with a distribution box equipped with three intake ducts. The technology, thanks to its flexibility, is applicable to the most diverse industrial sectors.

The pharmaceutical, chemical, food, logistics and transport of refrigerated fields, large-scale distribution: these are all areas in which it is possible to apply these innovations and make everything more environmentally sustainable.

The words of Maurizio Ascani

L’Ascani engineer he has declared:

“I am fascinated by the mechanics of the engines and above all the turbo technology, which allows us to reuse the energy otherwise wasted in the atmosphere. And that became a winner when it was linked to the Diesel engine. Without the turbo, in fact, the diesel would not have had the performance and diffusion it has today. With my team, we applied the turbo to the coolers and experienced that the solution worked. The times were ripe: the idea went well with the times “.

Leave a Reply

View Comments