In this article we are going to explore the world of 3D printing from different aspects: from productivity to sustainability, with a particular eye on materials

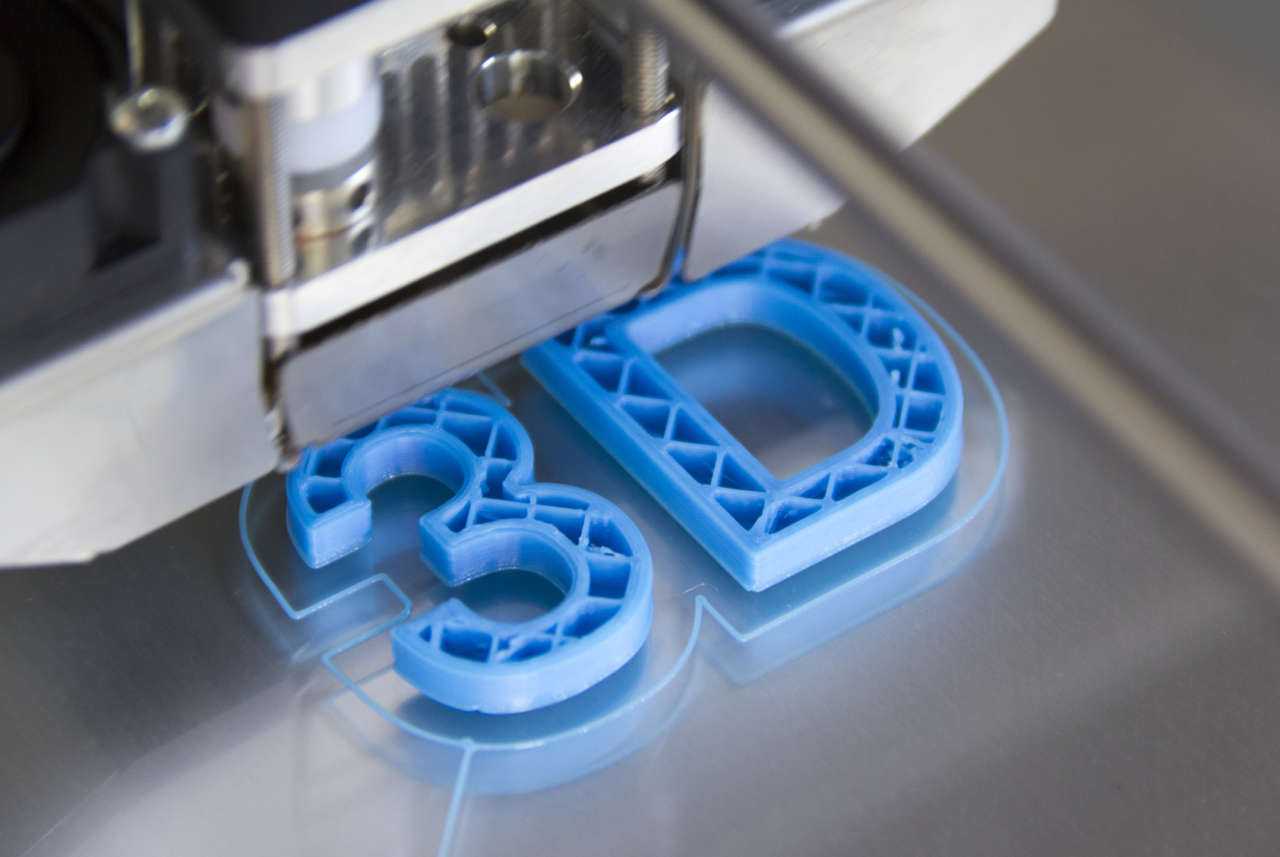

Today’s world has also seen the birth and development of 3D printing, also called, by industry experts, rapid prototyping. It is an additive technology that allows you to create a three-dimensional object layer by layer, starting from models designed on the PC. What are the advantages and the materials used? Let’s find out together in this dedicated article.

Productivity

3D printing offers several productivity benefits:

- Speed: 3D printing allows you to create prototypes or finished products in much less time than traditional methods, thus accelerating the development and marketing process

- Flexibility: the technology allows the creation of complex and customized geometries, otherwise difficult to achieve with traditional methods, thus guaranteeing greater design freedom

- Efficiency: 3D printing significantly reduces material waste and production costs, optimizing the use of available resources

Sustainability

And what about availability? Also in this case, 3D printing guarantees some advantages in environmental terms:

- Reduction of waste: with this technology only the materials necessary for the creation of objects are used, minimizing waste

- Sustainable materials: biodegradable, recyclable or low environmental impact materials can be used

- On-demand production: it is possible to produce only the necessary objects, thus avoiding overproduction and accumulation of inventories

- Reduction of emissions: On-site production reduces emissions related to the transportation and handling of goods

Materials

As far as materials are concerned, there really is a plethora of them and you will find them all described, in detail, on the FAMA 3D website. Below we list some of them:

- Nylon PA 12 Classic: it is the most versatile, economical, resistant and high-performance material that allows you to produce both prototypes and functional pieces.

- Nylon PA 12 White: similar to the Classic, but the Nylon is white in color and this allows different colors of the surface to be obtained through the immersion process.

- Nylon PA 12 Multicolor: with this Nylon you will have the resistance of PA 12, but with the possibility of directly printing any color and texture.

- Nylon PA 12 GB: a more rigid Nylon because it has 40% glass microspheres added. Greater wear resistance.

- Nylon PA 11: durable and environmentally friendly material with high wear resistance and low friction.

- 316 stainless steel: with a matte finish, this material allows you to obtain extremely resistant complete parts, but requires the presence of additional supports during printing.

- Aluminum: also in this case with a matte finish, similar to steel, very resistant, but requires additional supports during printing.

- Resins: generally used for components for aesthetic use or which require particular applications such as transparency or flexibility.

- TPU: flexible and rubbery material, maximum design freedom.

- Direct Extrusion: innovative technology that allows for a much greater extrusion speed and allows the creation of very large parts at low costs.

3D printing will also be available soon titanium.

Continue to follow us here on techgameworld.com!

Leave a Reply

View Comments