In this article we will have the pleasure of showing you 5 examples of the use of 3D printing that you would never have expected

For years, the hype around 3D printing has captured the public with visions of a future that included a 3D printer in every home that haven’t materialised. However, the possibilities of 3D printing were undeniabledespite the youth of the technology and the relatively low number of possible applications achievable in the past.

5 examples of using 3D printing

The initial excitement masked legitimate and growing business applications for 3D printing. With the proliferation of high-performance desktop and benchtop printers entering the market, we are now seeing a wider variety of companies expanding their product offerings with 3D printing. In order to be able to offer ever better results to its customers. But what is possible with 3D printing?? Here are 5 examples of use that you don’t expect and that testify to the wide field of application of this technology.

5 examples of using 3D printing: the next generation of 3D printed surgical instruments

Ten years ago, there was still little talk of the dramatic impact 3D printing could have on the medical industry, from the creation of advanced medical devices to custom-made surgical guides for patients. Restor3d was among the first companies to exploit the potential of 3D printing and has greatly improved the delivery of surgical treatments by printing specific polymer instruments for cervical spine implants. With a production line of more than 25 Formlabs 3D printers, its teams are already hard at work printing the next generation of surgical instruments. For surgeons, the use of this system of sterile instruments, individually packaged and specific for each operation, means:

- Replacement of large and expensive surgical trays

- Ability to iterate designs and quickly introduce new tools or features as needed

- Dramatically reduce supply chain and sterilization costs for hospitals

- End-use parts for high-performance footwear

Footwear sector

The sports footwear sector has long relied on technology to optimize the performance of its products. Now, with the advent of digital workflow, you have more customization options available. Some major brands such as New Balance, Adidas and Nike, intend to mass produce custom midsoles from 3D printed materials. As in other industries, digital workflow will complement traditional production methods: the essential and highly customized components of each product will be entrusted to 3D printing, while the rest will be made according to conventional techniques.

Details

New Balance produces footwear with unique properties, for this teamed up with Formlabs to create a custom printing material that can stand up to everyday wear and tear. Footwear materials face a variety of environments, plus the need to withstand different levels of pressure thousands of times a day. Rebound Resin is designed to create elastic and resilient lattice structures, with energy return, tear strength, and elongation far superior to other Formlabs materials. Rebound Resin is strong enough to be used in gaskets and automotive interiors, yet light and flexible enough for use in the sole of a shoe.

One of the things we’re really proud of is the fact that this product offers runners a really different experience,

said Katherine Petreccageneral manager of the footwear department at the New Balance Innovation Design Studio.

True mass customization for the first time

3D printing opens the door to new possibilities and business opportunities. Objects that were previously too complex, expensive or impractical to produce using traditional methods can now be made at no extra cost thanks to digital technologies. This allows designers to take complete control and paves the way for the introduction of fully customizable consumer products. A great example is Gillette’s Razor Makerwhich gives customers the ability to personalize their razor handle by choosing from various designs and colors or by adding custom text.

For Gillette, Razor Maker represents a crucial step in our personalization journey, where innovative technologies combine with new business models to deliver products as unique as our consumers,

explained Donato DiezGlobal Head of Gillette Brand and Razor Maker.

Reiventare lo storytelling

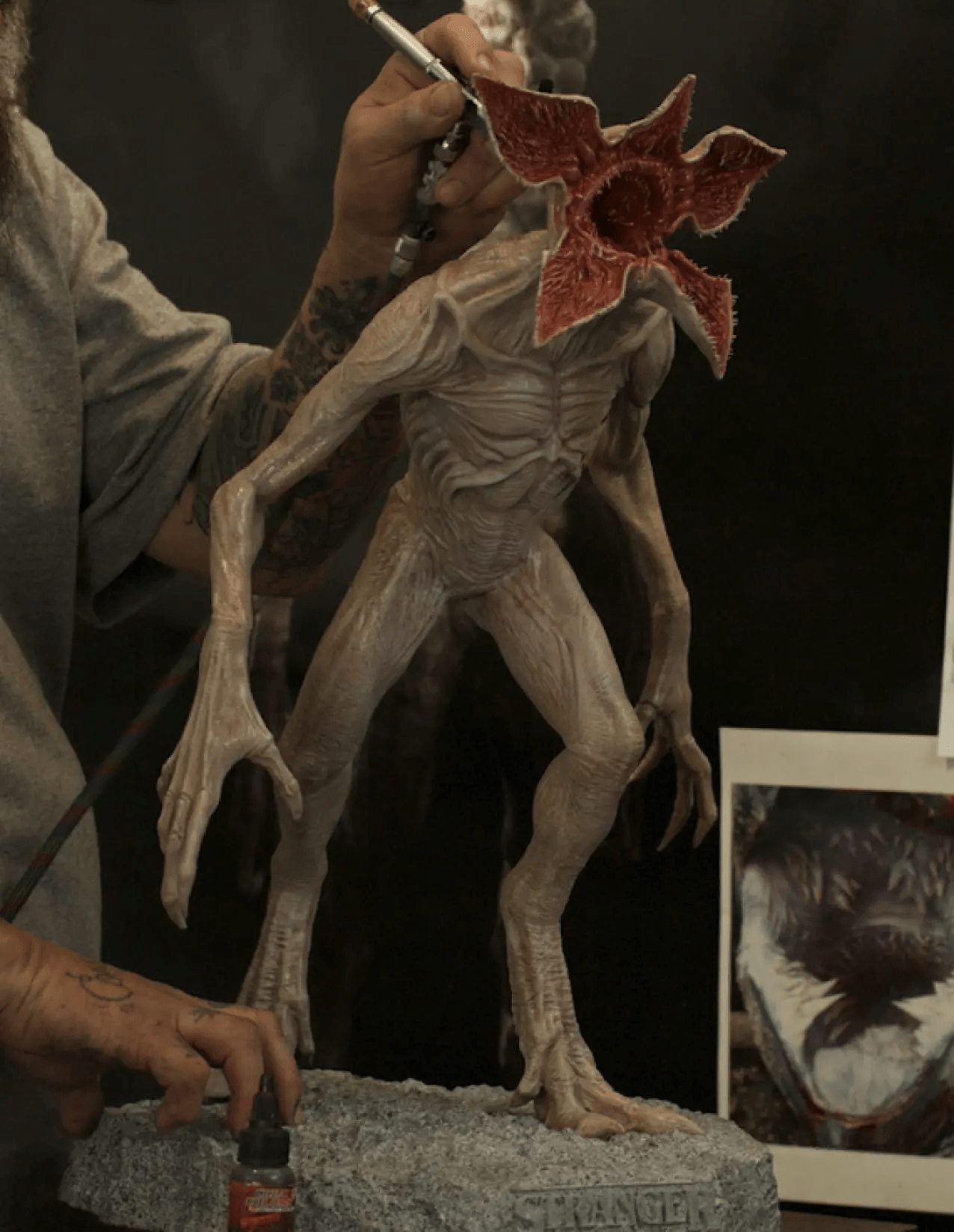

3D printing has already found its place within Hollywood filmmaking and is widely used for visual effects and costumes.

Where once the creation of fantastical imaginary creatures required painstaking manual work, the increasing pressure and tight deadlines imposed by the modern film industry have led to the development of a faster method for creating such effects. Design and visual effects studios like Aaron Sims Creative now use a hybrid approach based on real-world effects augmented by digital workflow. In order to create new collaboration opportunities and reduce the lead times necessary to bring projects to life.

The Demogorgon was one of the first prints we made using our Formlabs 3D printers, and we were blown away. Before that we had always outsourced printing. The ability to print in-house and see the design we had helped create from the very beginning take shape before our eyes was an amazing feeling. It was like going back to the days when we sculpted characters in clay,

said Aaron Sims.

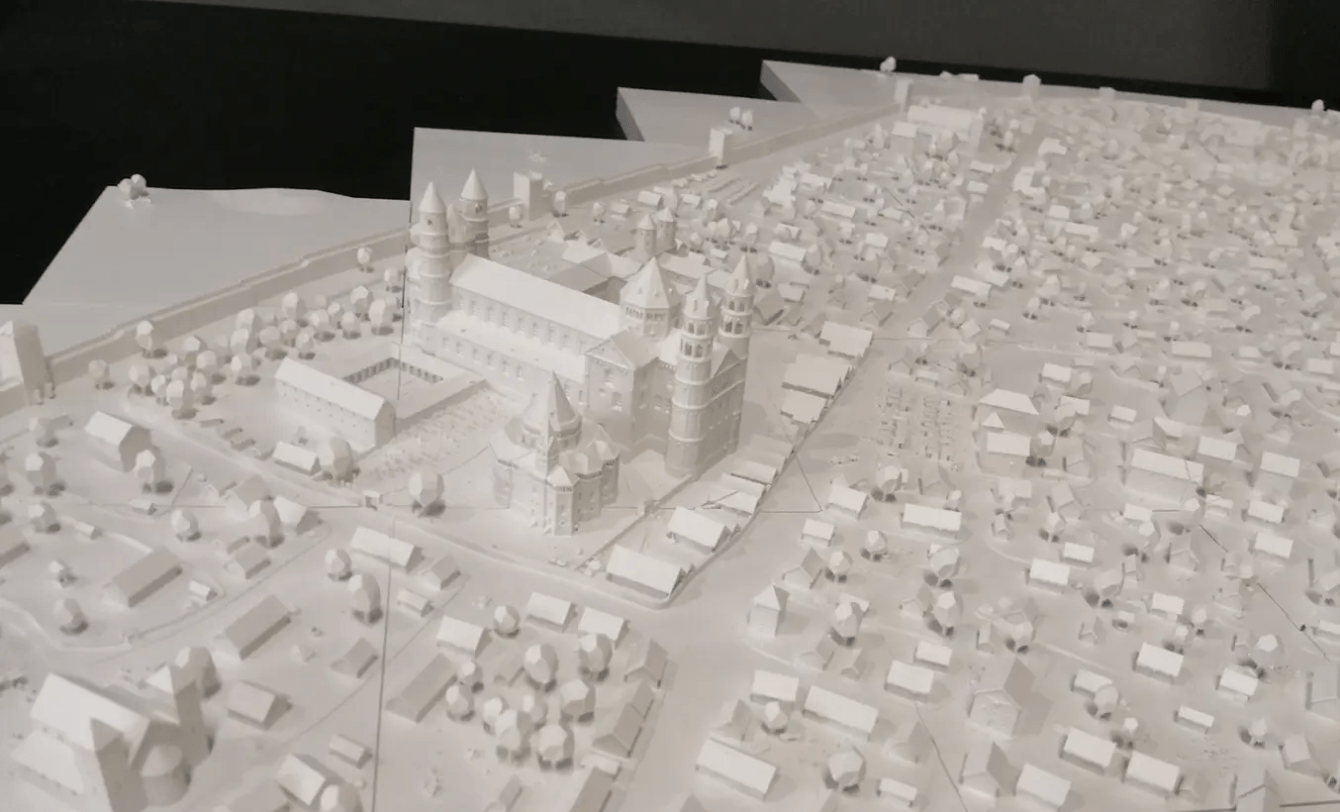

Bring ancient cities to life

As an industry founded on geometric design, prototyping and modeling, architecture benefits enormously from 3D printing technology. In addition to reducing model production time, 3D printed models allow architects to more confidently predict the physical effects of certain design features. By observing a layout produced with a full range of materials, it will be possible to measure aspects such as the distribution of light within the structure with extreme precision. But the use case for 3D printing goes beyond individual models: Some companies are recreating entire cities. Such as, for example, the Mainz Institute of Architecture, University of Applied Sciences (Hochschule Mainz). The result was an extraordinary exhibition featuring six large-scale models of cities in the 1800s and 1250s.

And you? What do you think of these examples of the use of 3D printing ? Let us know with a comment below and always stay tuned to TechGameWorld.com for other news and reviews from the world of technology (and beyond!).

Leave a Reply

View Comments