What are the different 3D printing technologies and how to use them? Let’s try to find an answer together

3D printing is a relatively new technology that has had a huge impact on production and prototyping of products all over the world. It is in fact an additive technology that is, adding material little by little in order to create an object. It’s about a quick and low cost solution which allows you to create even very complicated objects. In this article, we will focus on the different types of 3D printing technologies and their uses.

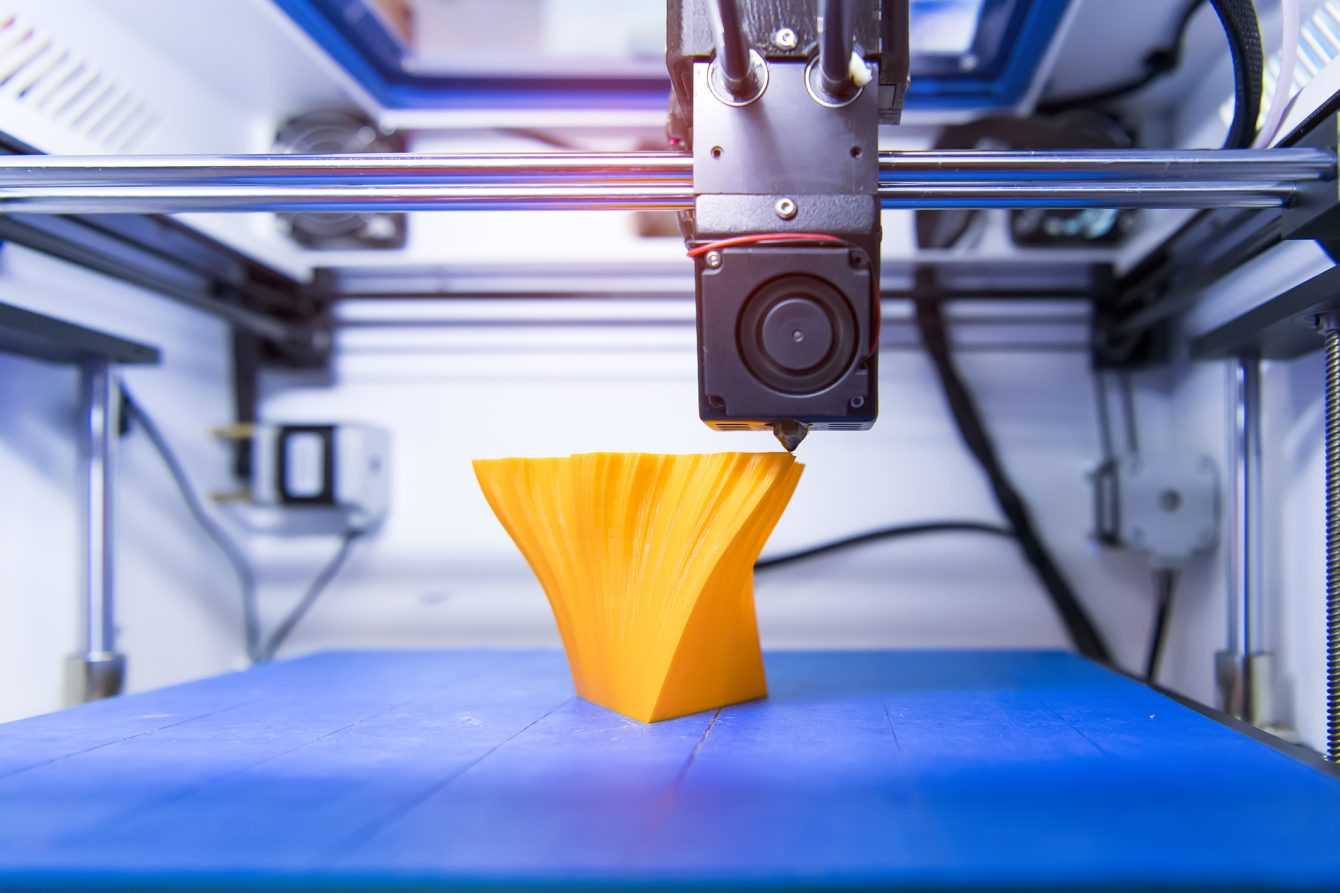

Fused Deposition Modeling (FDM): The most common 3D printing

FDM printing is one of the most common and cost-effective 3D printing methods on the market. This technique print objects by adding layer by layer of the melted plasticthus creating a three-dimensional model. To produce an object with this technique, users must create a 3D CAD digital file and upload it to the FDM printer. FDM printers are mainly used to create prototypes and functional parts, although some artistic and creative applications are emerging more recently as these machines are becoming more and more precise in reproducing details.

Stereolithography (SLA), for absolute precision

SLA 3D printing uses a photopolymerization process to create three-dimensional models. SLA technology uses a photosensitive resin that is exposed to UV rays so that it solidifies as much as possible. Users can then extract the created objects from within the resin, usually using a solution to dissolve the resin that is not hardened by light. This 3D printing technology is significantly faster than other technologies and can be used to create very rigid and precise objects – it is a technique similar to the one used to produce processors. However, it involves a considerable waste of material. This technology is mainly used for making molds, jewelry and other small objects.

Selective Laser Sintering (SLS), stampa 3D per metalli

SLS 3D technology uses a laser beam to melt material powders together to create a three-dimensional model. The materials used in this 3D printing technology are usually polymeric, metallic or ceramic. This technology is used for the production of functional parts and prototyping, and the objects created have great mechanical properties and high quality. It is a very promising technology in the industrial field because it also allows you to work with metals.

Binder Jetting, imprecise but strong 3D printing

Binding joint 3D printing technology uses a spray lithography technology which combines pieces of dust and an adhesive to create three-dimensional objects. Items created with this technology are quite durable but may take some time additional finishing work to make them more robust. This technology is mainly used for printing functional parts, prototypes and automotive parts, as well as for the production of ceramic and metal parts.

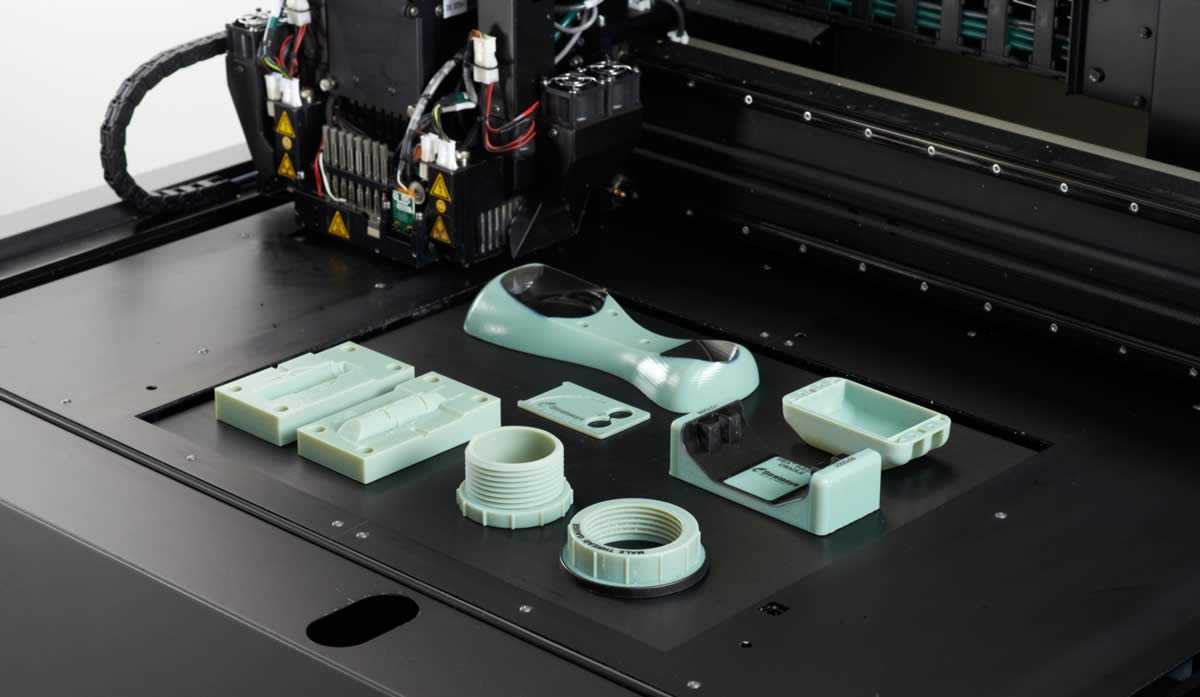

PolyJet, very high resolution and details

PolyJet 3D technology uses a matrix of printing nozzles to deposit small drops of material molten polymer. This technology allows you to create parts with high resolution, detail and smooth surface. This technology is mainly used for the production of prototypes, medical models, automobile parts and consumer products.

In general, the applications of this technology are vast: it ranges from customized tooling to mass production of large-scale products. 3D printing technology is constantly developing and we can find both household and industrial models. But if you do not want to invest directly in a professional 3D printer or because you are not yet sure which technology to use, you can rely on 3D printing services such as 3DEXPERIENCE marketplace. These are industry professionals who have many different machines at their disposal and a team of experts who can help you create the object you want. That’s all from the electronics section, keep following us!

Leave a Reply

View Comments