Il CERN (European Organization for Nuclear Research) is a famous research center for particle physics that houses the largest and most powerful particle accelerator dn the world, the Large Hadron Collider (LHC), using 3D printers for the construction of particle detectors.

CERN and 3D printers

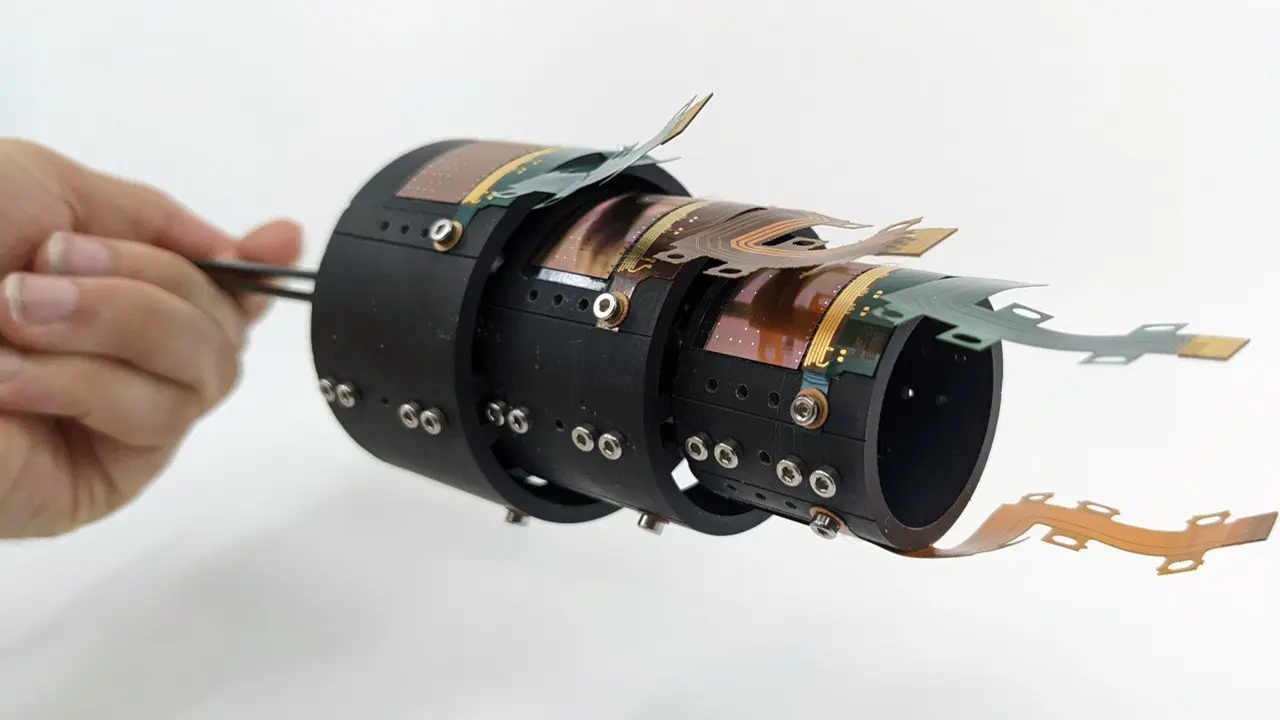

For more than 6 years, CERN has been using 3D printing for various applications through its Experimental Physics Detector Technology (EP-DT) department. In all, it uses two stereolithography 3D printers: Formlabs Form 2 and una Form 3Limportant for the research and development of the new generation of particle detectors for the LHC.

The use of these 3D printers has made it possible to cut various development times and costs, finding new layout solutions that cannot be obtained with traditional processing. In particular, Formlabs materials are used for prototypes, but also for molds, assembly tools and detector testing.

The researchers underwent training, provided by Formlabs, to use the printouts safely and independently. In this way it has often happened that some researchers have created the projects themselves using CAD modeling programs by sending them to the printer.

The CERN team also tested printers with FDM technology, unfortunately finding a lower quality of prints than those made with SLA technology.

3D printed polymeric materials are being used more and more in LHC experiments. However, there are severe requirements to be respected, deriving from exposure to doses of radiation in the experimental area which can modify the mechanical properties and which require a specific qualification of the printed materials.

Resins and the future of 3D printing in research

Massimo Angelettimechanical engineer, member of the department of Experimental Physics Detector Technology (EP-DT) and involved in the construction, assembly and installation of particle detectors, hopes in the future to have materials characterized for high radiation environments, so as to extend their use in functional parts of the detectors in the experimental area.

For example, the most used resins during the prototyping process of particle detectors are the Black Resin and the Clear Resinbut the team is already testing the Rigid 4000 Resin and the Rigid 10K Resin to possibly manufacture parts for use in the future.

“3D printers make everything easier and faster,” he said Massimo Angeletti.

“You own the process from start to finish. You create the files yourself and send them to the printer, and that definitely pays off. 3D printing also allows for many iterations. In a few days, you have the final piece that would have been delivered weeks later if it had been sent to a third party. It’s incredible. It would be really nice to further implement 3D printed parts and minimize standard production.”

For the future, the goal is a almost entirely 3D printed detector, except for electronics, sensors and components. Angeletti also hopes to use new radiation-qualified photopolymers in possible experiments.

Learn more about Formlabs at formlabs.com

Leave a Reply

View Comments