A Colonia Ford inaugurates the first zero-emission plant, theElectric Vehicle Center. A highly specialized production facility based in Germany. Where the new generation of electric cars of the Blue Oval will be built for millions of European customers.

Inizia l’era Ford Electric Vehicle Center

With a two billion dollar investment, Ford transforms historic Niehl plant. In Cologne, focusing on the highly skilled German workforce and the future of automotive production in Europe.

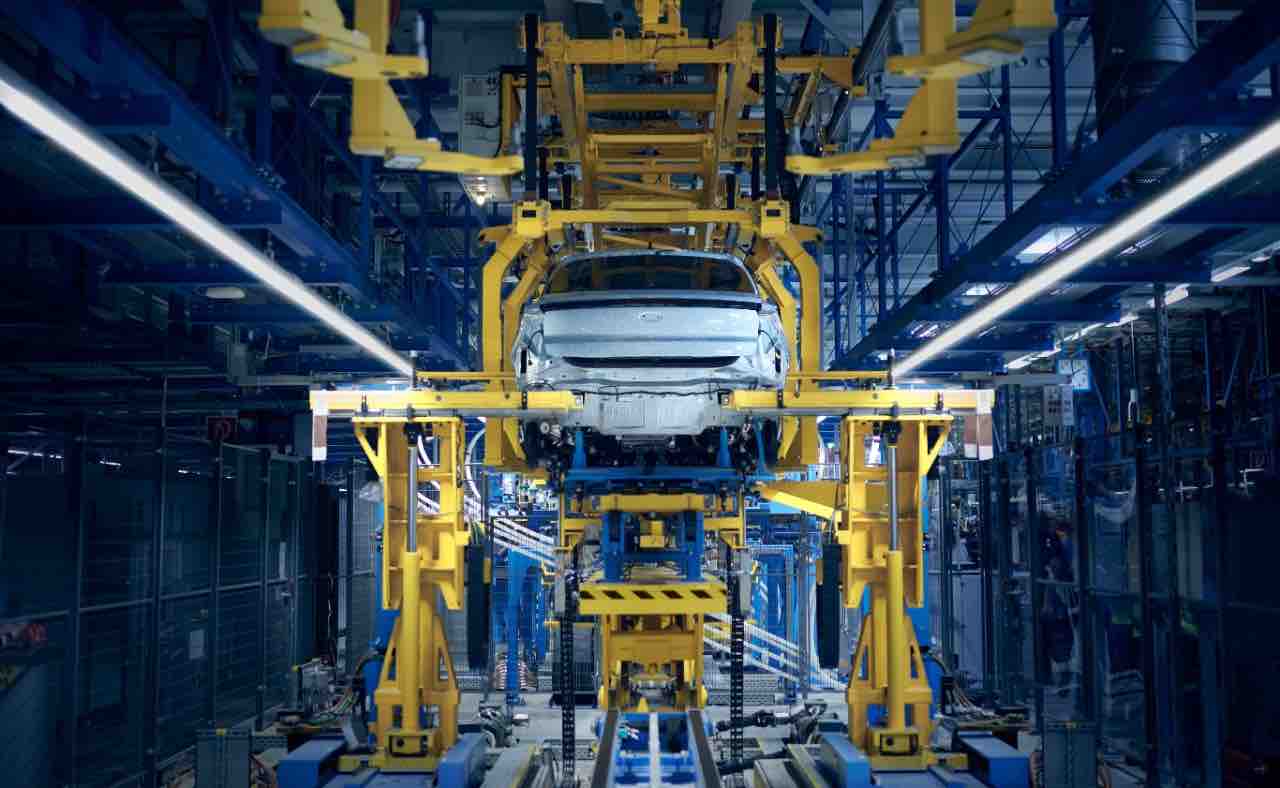

Designed to be highly efficient. The site extends over an area of 125 hectares and is equipped with a new production line.

Battery assembly and state-of-the-art equipment and automation, enabling an annual production capacity of over 250,000 electric vehicles. After the successes of Mustang Mach-E, E-Transit e F-150 Lightning.

The new Explorer will be built in the Electric Vehicle Center

Ford now unveils its fourth all-electric vehicle globally, the new Explorer, the first electric vehicle built in Cologne and to be followed by a second zero-emission model, a sporty crossover.

Ford inaugurates the first zero-emission plant in Cologne, source press office

Ford inaugurates the first zero-emission plant in Cologne, source press office

will be theElectric Vehicle Center of Cologne the primo plant Of assembly Ford’s Zero Emissions globally and supports the company’s plans to achieve carbon neutrality across its entire European manufacturing footprint, including logistics and suppliers, by 2035.

“The opening of the Electric Vehicle Center in Cologne marks the start of sustainable production for the construction of electric vehicles in Europe” said Ford Executive Chair Bill Ford. “This plant will be one of the most efficient and environmentally responsible. I am excited to continue working towards a zero-emissions future for our children and grandchildren.”

The words of the German Chancellor

German Chancellor Olaf Scholz declares: “The Electric Vehicle Center represents a new beginning and is the largest investment in the company’s history at the Ford plant in Cologne. This is good news for Cologne, for the automotive industry in Germany, for e-mobility and for the future.”

From the Model A to the new all-electric Explorer: a new era for Ford in Europe

The opening ofElectric Vehicle Center is a new chapter in the long history of the plantBlue oval a Colonia. Dal 1930 is the heart of the European automotive industry. Iconic vehicles built on this site include the Ford Model A, Taunus, Capri, Granada and Fiesta.

For over 90 years, the Ford plant in Cologne has produced more than 18 million cars, has been one of the most efficient Blue Oval plants in the world and has allowed millions of Europeans of different generations to move freely.

Martin Sander, General Manager, Ford Model and Europe declares: “The Cologne Center marks the beginning of a new era for Ford in Europe”.

“We are once again redefining car manufacturing, deploying advanced technologies to build fully connected vehicles and specialized software to meet our customers’ increasingly oriented demand for zero-emission mobility.”

The heart of the plant

At the heart of the Cologne plant are digital advances that connect machines, vehicles and workers. The implementation of self-learning machines, of autonomous transport systems. And real-time big data management.

These are an integral part of improving the efficiency of production processes. And improvement over time, and guarantee high quality at the same time.

Ford is also taking it one step further to support – not replace – human excellence. New cognitive and collaborative robots and augmented reality solutions will support employees and increase efficiency and data exchange with other plants to share experiences in real time.

A hub of zero-emission electric vehicles: Ford is making its ‘Road to Better’ plan a reality

To reach the carbon neutrality, Ford will reduce l’energy use and emissions at the German plant through the installation of new processes, machinery and technologistsAnd. All the electricity and natural gas needed to operate the plant are carbon neutral, as they are 100% certified electricity and biomethane.

The heat required to heat the plant and processes is emissions neutral, as the local energy supplier will offset the corresponding assembly plant emissions on behalf of Ford. The heat is generated by an external power plant and waste incineration plant and supplied to Ford through a dedicated steam network.

Il local energy supplier expects to reduce its operational emissions for heat supply by approx 60% in 2026 and eliminate them completely by 2035. As soon as it is fully operational, theFord’s Electric Vehicle Center in Cologne will be independently certified as carbon neutralL. This independent certification will be verified and reconciled on a regular basis with the purchase of high quality carbon offsets for the remaining emissions.

The technological upgrade of the Electric Vehicle Center in Cologne is accompanied by an improvement of biodiversity and green spaces in the existing factory area. The measures installed include new vegetation, the transformation of non-green areas into areas rich in vegetation and, therefore, an ideal habitat for many species of insects and birds.

“The zero-emission Electric Vehicle Center in Cologne is an important showcase for the automotive industry for the transition from traditional production to the production of electric vehicles,” concluded Sander. “The structures and processes have been designed by our engineers to maximize efficiency and minimize environmental impact, helping Ford become carbon neutral in Europe and support our global decarbonization plan.”

Leave a Reply

View Comments